Welcome to visit our website of Charming Chemical Equipment Co.,Ltd.

home > Product Center > Double-conical Rotary Vacuum Dryer > Conical Bottom Helical Ribbon Mixer Vacuum Dryer

Conical Bottom Helical Ribbon Mixer Vacuum Dryer is a kind of multi-functional mixing and drying machine, it is a batch type fully closed process equipment for solid mixture and vacuum drying, which is widely used in chemical industry, fine chemical industry, food industry and pharmaceutical process industry. The corrosion resistance and cleanness of the cylinder metal material (Glaslined steel, Stainess steel, Hastelloy & etc.) is especially suitable for medium in the above industries.

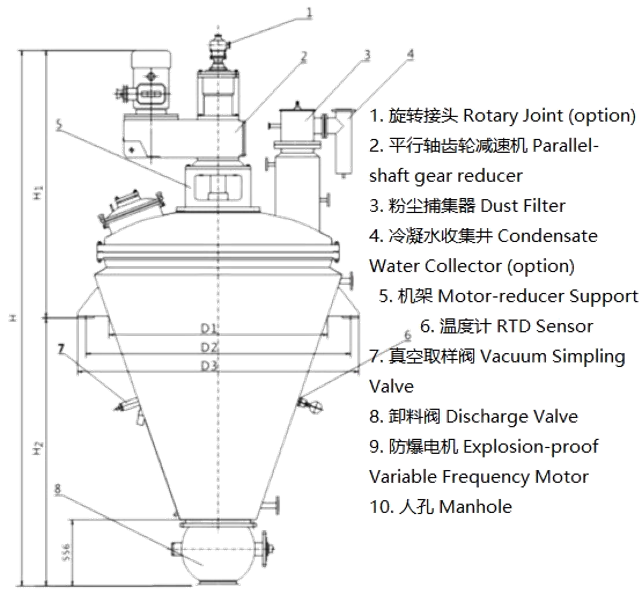

Conical Bottom Helical Ribbon Mixer Vacuum Dryer is a vertical type pressure vessel equipment. Its constructure mainly includes a cylindrical upper vessel with a head or only a flanged head, a flange mounted type detachable movable conical bottom vessel with discharge valve, heating/cooling jacket, agitating/stirring device, motorgear device, dust filter, temperature and pressure measurement device and etc.,also canbe assembly with hollow shaft heating system, online weighting device, online washing device(CIP/MIP), online sampling valve, SIP system, vacuum system, external hot water/thermal oil circulating system, PLC control system.

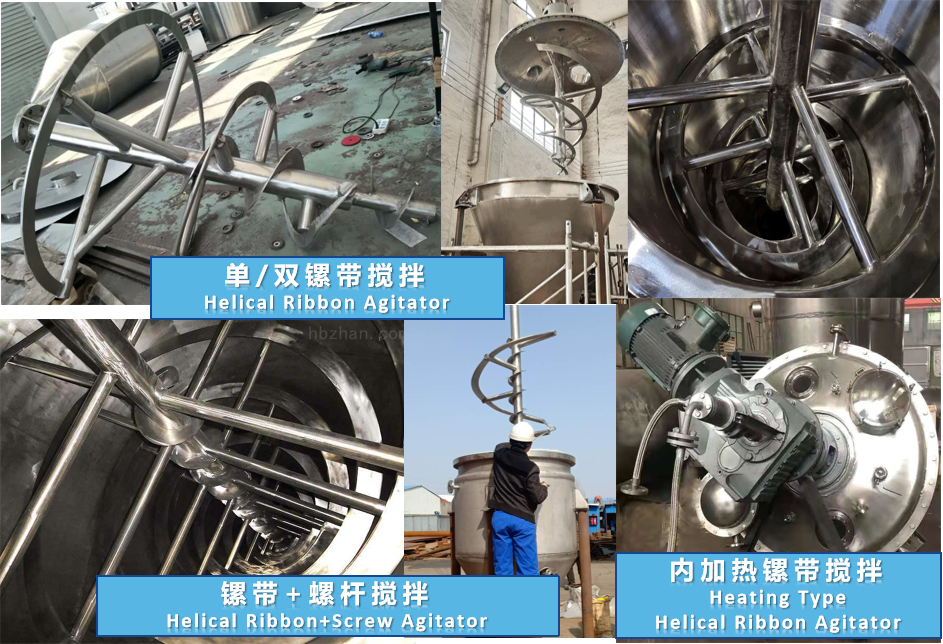

Helical ribbon type agitator is a kind of with low shear force that lifted and dropped freely along the inner wall of the cone dived by motor&reducer, the material continuously sheared and dispersed to ensure all materials in the cone can be fully moved, for the materials are not squeezed by any other external force, so avoiding the ineffective friction between materials and equipment as well as between material particles, and eliminating the possibility of material caking during the drying process, which greatly improves the mixing and drying efficiency of materials.

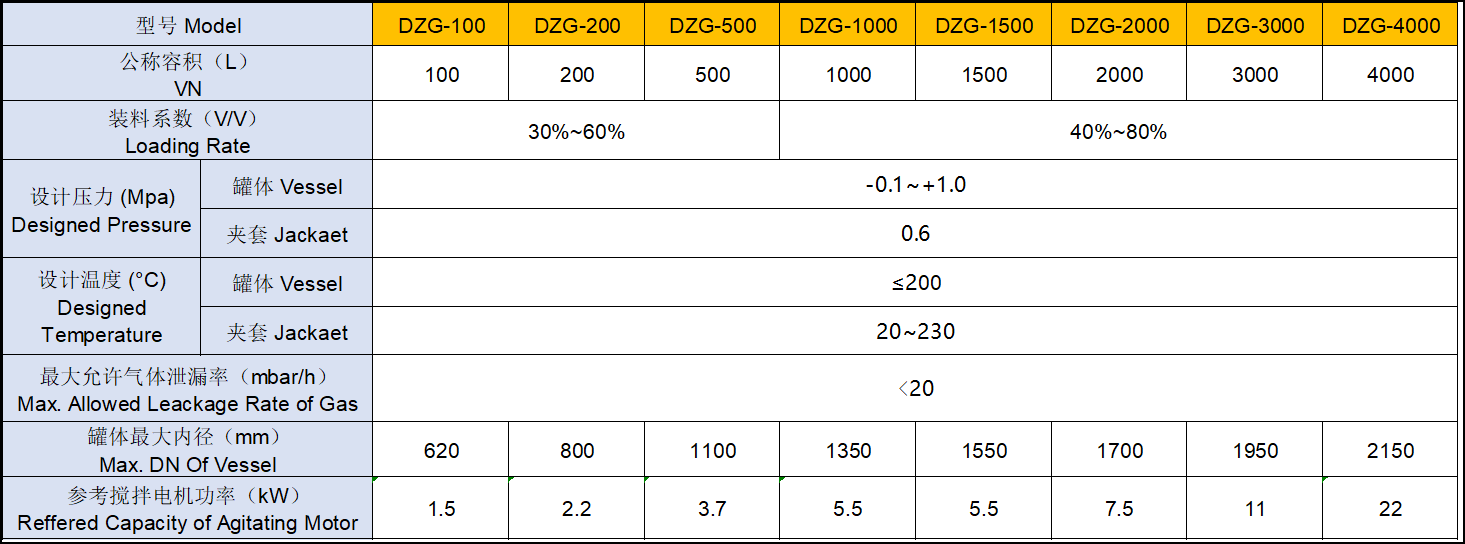

☆ Capacity: 100L to 4000L

☆ Loading Rate: 0.3 to 0.8

☆ Heat Exchange Area积: 4.1m2 to 22m2

☆ Designed Parameters:

Vessel Pressure力: -0.098 to 1.0Mpa;

Jacket: 0.6Mpa;

☆ Agitating Speed: 0 to 25 rpm

☆ Working Medium: According to the construction material

☆ High drying efficiency

☆ High mixing accuracy

☆ Low shear helical ribbon stirring, without damaging the shape of materials

☆ Extra heat exchange surface area possible by add hollow agitator heating system

☆ Sanitary mechanical seal special for GMP

☆ Easy installation and maintenance

☆ Design and manufacture according to the condition and requirement of customer

Generally, the drying process of Conical Bottom Helical Ribbon Mixer Vacuum Dryer will under the vacuum condition by jacket heating:

Vacuum drying (VD) has some distinctive characteristics such as higher drying rate, lower drying temperature, and oxygen-deficient processing environment. It is conceptually the ideal method for drying heat and/or oxygen sensitive materials due to the advantage of removing moisture at low temperatures and minimizing the possibility of oxidation reactions.

During vacuum drying, high-energy mloisture molecules diffuse to the surface and evaporate due to low pressure. Due to the absence of air and bacteria, vacuum drying prevents oxidation and maintains the color, texture, and flavor of the dried products.

Vacuum-drying is proposed to alleviate some disadvantages of hot-air-drying, such as surface hardening and dispersion. During vacuum drying, the rate of evaporation increases (at a fixed temperature) since the boiling point of moisture is reduced. Vacuum-drying consequently requires less drying time than conventional hot-air-drying and in most cases results in a higher quality dried product.

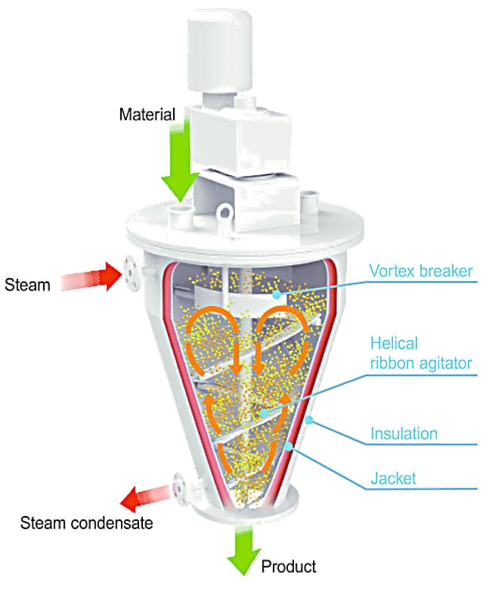

Conical Bottom Helical Ribbon Mixer Vacuum Dryer is special designed for solid mixing & drying: 1/ The variable frequency motor via reducer drive the helical ribbon agitator rotating to achieve the material lifting along the inner wall of conical vessel from bottom to top; 2/ and then falling down by weight from top to bottom; 3/ During upper process the material are forced to vertical and axial motion in the vessel continuously and contact the inner wall for heating, the heat is mutually diffused in the materials by relatively convective and mixed, and achieving the effect of heating and drying in a short time; 4/ The water/solvent inside the material is constantly evaporated and the vapor is led out by the vacuum pump. If the vapor/liquid needs to be recovered, the system can be adding a condenser and recovery the liquid to a storage tank, this condenser can be installed before or after the vacuum pump, depending on the properties of the solvents;5/ The dryed material discharge by the bottom valve.

The referenced parameter of Conical Bottom Helical Ribbon Mixer Vacuum Dryer as such:

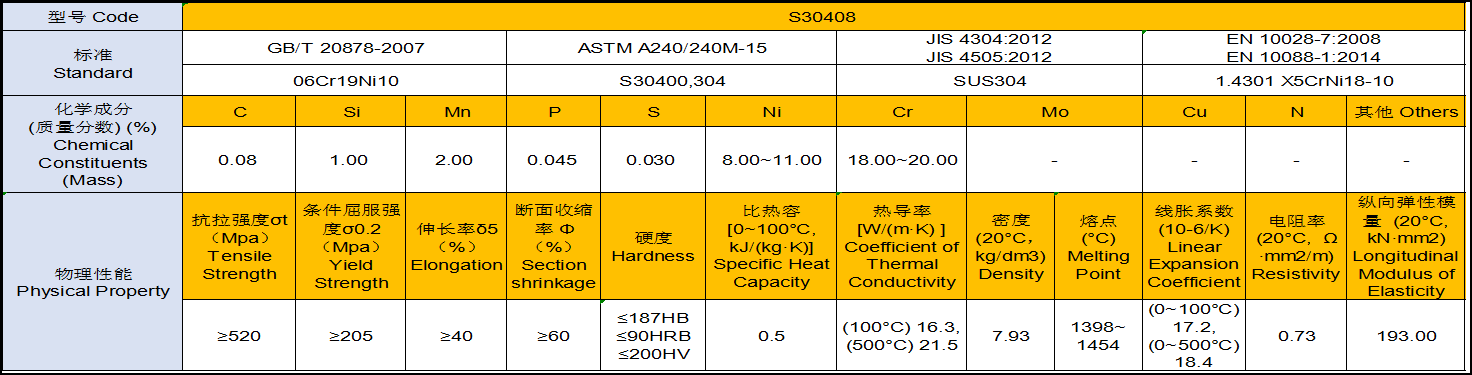

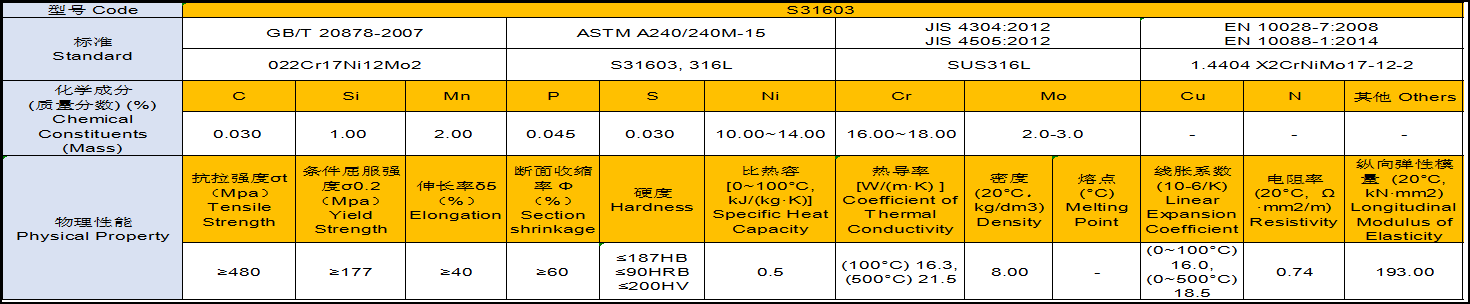

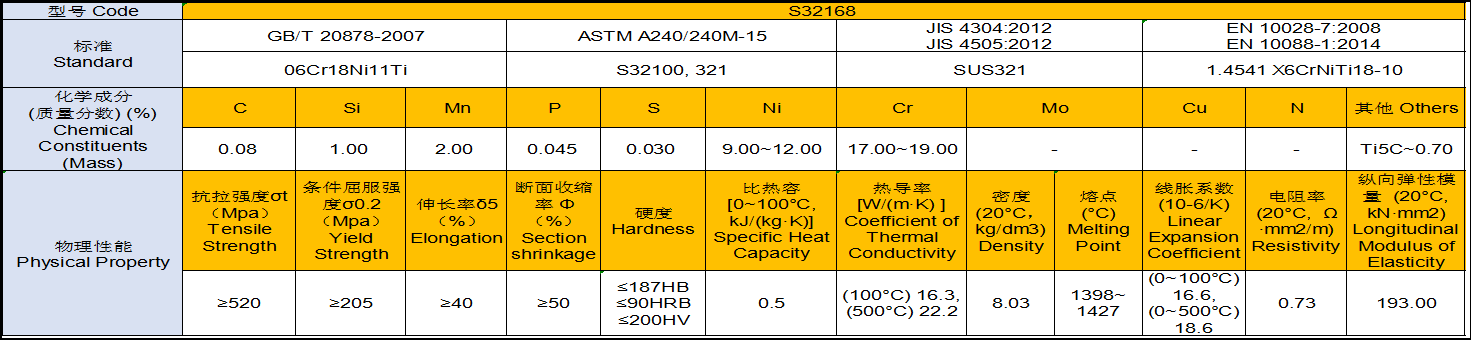

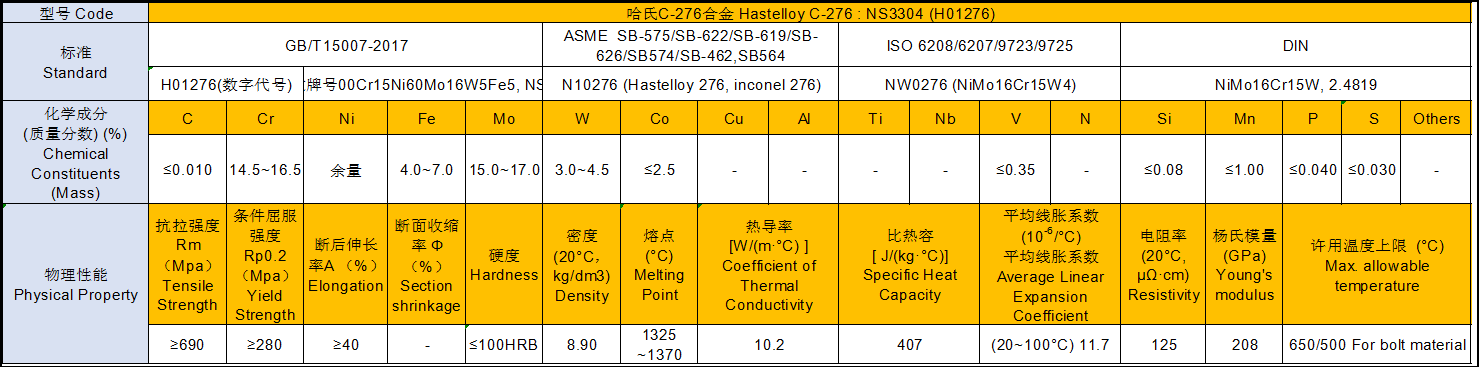

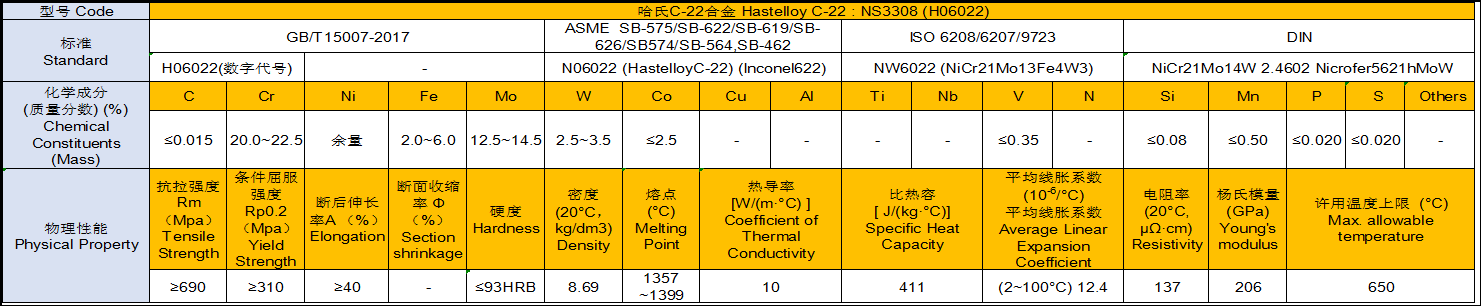

According to the property of working media, the constructure material of Conical Bottom Helical Ribbon Mixer Vacuum Dryer canbe selected by stainess steel 304/304/316L/321/2205 and hastelloy C-276/C-22。

◆ Model/Code/Type 304(S30408)/316L(S31603)/321(S32168) are chromium-nickel alloys and 2205(S31803/S32205) is middle alloy duplex stainless steel use stainless steel that common use in manufacturing of ANF/ANFD.

◆ Hastelloy is an ultra-low carbon nickel-based corrosion-resistant alloy, which is mainly divided into two categories: nickel-chromium alloy and nickel-chromium-molybdenum alloy. Commonly used hastelloy model for pressure vessels include C-276(Ni-Cr-Mo-Fe-W alloy)&C-22(Ni-Cr-Mo-W alloy). The characteristics of hastelloy include high uniform corrosion resistance, excellent local corrosion resistance, excellent stress corrosion cracking resistance and easy welding and manufacturing suitable applicating in various workingenvironments of oxidizing and reducing media.

Model/Code/Type 304 is the most widely used kind of chromium-nickel austenitic stainless steel with good corrosion resistance, heat resistance, low temperature strength and mechanical properties; good hot workability by stamp and bend, no heat treatment hardening phenomenon (application temperature -196 ℃ to 800℃). It has good processability and weldability. The disadvantage is corrosion very fast in the presence of chloride ions, even exceeding than carbon steel.

Model/Code/Type 316L is the second widely used kind of low-carbon content chromium-nickel-molybdenum austenitic stainless steel,the added molybdenum content improves resistance to pitting corrosion and provides greater resistance to acids and localized corrosion caused by chloride ions. 316L have carbon contents below 0.03% to avoid corrosion problems caused by welding. It is generally accepted that 316 has better corrosion resistance and is more corrosion resistant than 304 in high temperature environment. However, the corrosion rate is very fast in high temperature concentrated sulfuric acid environment.

Most of the existing 316L stainless steel plates for pressure vessels in the market are produced according to American standards. The American standard stipulates that the Ni content of 316L is 10 ~ 14%, and the Japanese standard stipulates that the Ni content of 316L is 12 ~ 15%. Therefore, when purchasing 316L products, customers need to confirm whether the products refer to ASTM or JIS standards.

Model/Code/Type 321 is chromium-nickel austenitic stainless steel, its properties are very similar to 304. However, due to the addition of metal titanium, it effectively controls the formation of chromium carbide and has better intercrystalline corrosion resistance and high temperature strength. 321 austenitic stainless steel has good corrosion resistance in the atmosphere. It applicated in outdoor equipment with high requirements for intercrystalline corrosion resistance, heat-resistant parts and parts with difficulty in heat treatment. It is widely used in petrochemical, electric power, bridge, automobile and other industries.

Model/Code/Type 2205 is middle alloy duplex stainless steel, it has the characteristics of both austenitic and ferritic stainless steel.It combines the excellent toughness and weldability of austenitic stainless steel with the high strength, thermal conductivity and chloride stress corrosion resistance of ferritic stainless steel. 2205 is a nickel saving stainless steel which has excellent pitting corrosion resistance. But, 2205 still has the high-temperature brittleness tendency of high chromium ferritic stainless steel, which is not suitable for working conditions higher than 300 ℃. It is commonly used in heat exchangers, evaporators, chillers and devices resistant to seawater, chloride, high-temperature concentrated nitric acid and etc. in oil refining, fertilizer, papermaking, petroleum and chemical industry.

Hastelloy C-276(UNS N10276) was the first wrought, nickel-chromium-molybdenum material to alleviate concerns over welding (by virtue of extremely low carbon and silicon contents). Like other nickel alloys, it is ductile, easy to form and weld, and possesses exceptional resistance to stress corrosion cracking in chloride-bearing solutions (a form of degradation to which the austenitic stainless steels are prone). With its high chromium and molybdenum contents, it is able to withstand both oxidizing and non-oxidizing acids, and exhibits outstanding resistance to pitting and crevice attack in the presence of chlorides and other halides. Furthermore, it is very resistant to sulfide stress cracking and stress corrosion cracking in sour, oilfield environments. Typical chemical process industry applications include reactors, heat exchangers, and columns.

Hastelloy C-22(UNS N06022) is one of the well-known and well-proven nickel-chromium-molybdenum-tungsten materials, the chief attributes of which are resistance to both oxidizing and non-oxidizing chemicals, and protection from pitting, crevice attack, and stress corrosion cracking. Its high chromium content provides much higher resistance to oxidizing media than the family standard, C-276 and imparts exceptional resistance to chloride-induced pitting, an insidious and unpredictable form of attack, to which the stainless steels are prone. Like other nickel alloys, C-22 is very ductile, exhibits excellent weldability, and is easily fabricated into industrial components.Typical chemical process industry applications include reactors, heat exchangers, and columns.

上一篇:暂无

下一篇:暂无